Nigeria’s maritime sector plays a crucial role in the nation’s economy, serving as the gateway for over 90% of its international trade. However, the sector is facing significant challenges, particularly at the ports, where bottlenecks have become a growing concern for the manufacturing sector. These bottlenecks not only disrupt the flow of goods but also have far-reaching implications for the economy, affecting everything from production timelines to the cost of goods.

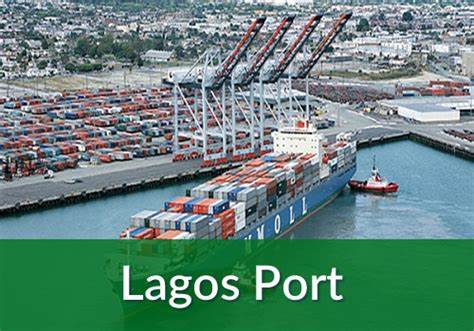

The Strategic Importance of Nigeria’s Ports

Nigeria’s ports, particularly the Apapa and Tin Can Island ports in Lagos, are among the busiest in West Africa. They are critical hubs for the import and export of goods, making them vital to the nation’s manufacturing sector. Manufacturers rely heavily on these ports to import raw materials and export finished products. Efficient port operations are therefore essential to ensure that goods move smoothly through the supply chain.

The Growing Concern: Bottlenecks at the Ports

Over the years, Nigeria’s ports have become notorious for congestion and inefficiency. Several factors contribute to these bottlenecks, including outdated infrastructure, poor road networks leading to the ports, inadequate capacity to handle the volume of traffic, and bureaucratic inefficiencies.

One of the most visible issues is the traffic congestion on the roads leading to the ports. The Apapa area, for instance, is infamous for its gridlock, with trucks often spending days or even weeks in line before accessing the port. This not only delays the movement of goods but also increases transportation costs, which manufacturers ultimately pass on to consumers.

The inefficiencies within the port operations themselves further exacerbate the problem. Slow customs processes, a lack of coordination among various agencies, and limited use of technology result in long delays for clearing goods. For manufacturers, these delays can disrupt production schedules, leading to missed deadlines and lost business opportunities.

Impact on the Manufacturing Sector

The bottlenecks at Nigeria’s ports have a direct and significant impact on the manufacturing sector. Delays in clearing raw materials and machinery needed for production can cause severe disruptions in manufacturing processes. This can lead to increased production costs, as manufacturers may need to pay demurrage charges for containers that are stuck at the port or resort to more expensive alternative transportation methods.

Moreover, the unpredictability of port operations makes it difficult for manufacturers to plan effectively. Lead times become uncertain, which can strain relationships with both suppliers and customers. For export-oriented manufacturers, these delays can result in missed opportunities in international markets, harming Nigeria’s competitiveness.

The overall effect is a reduction in the efficiency and profitability of the manufacturing sector, which in turn affects the broader economy. With manufacturing being a key driver of economic growth and job creation, the implications of port bottlenecks are far-reaching.

Addressing the Bottleneck: The Way Forward

To address the bottlenecks at Nigeria’s ports, a comprehensive and multi-faceted approach is needed. This includes both short-term solutions to alleviate immediate issues and long-term strategies to ensure sustainable improvement.

In the short term, there is a need for better traffic management and the development of alternative routes to reduce congestion on the roads leading to the ports. Implementing a more efficient system for scheduling truck arrivals could help reduce the number of vehicles queuing at any given time.

In the longer term, significant investments in port infrastructure are required. This includes upgrading existing facilities, expanding port capacity, and adopting modern technologies to streamline operations. The development of deep-sea ports, such as the Lekki Deep Sea Port, which is currently under construction, could also help ease the pressure on existing ports.

Reforming the regulatory environment is equally important. Simplifying customs procedures, enhancing inter-agency coordination, and increasing the use of digital platforms for processing and tracking goods could significantly reduce delays.

Conclusion

The bottlenecks at Nigeria’s ports represent a serious challenge for the manufacturing sector and the broader economy. Addressing these issues is critical to ensuring the smooth flow of goods, reducing costs, and enhancing the competitiveness of Nigerian manufacturers. With the right investments and reforms, Nigeria can unlock the full potential of its maritime sector, driving economic growth and development in the process.